Lecture 8 Preparation & Sterilization

Lecture 8 Preparation & Sterilization

- Sterilization

- cleaning

- All new apparatus, materials and instruments should be soaked in detergent overnight, thoroughly rinse and dried (do not expose materials that will corrode to detergent for > 30 min)

- Used items should be rinsed in tap water and immersed in detergent immediately after use, soak overnight, rinse in deionized water, dry in oven

- packaging→steam penetration, impermeable to dust, microbe, mite

- sterilization

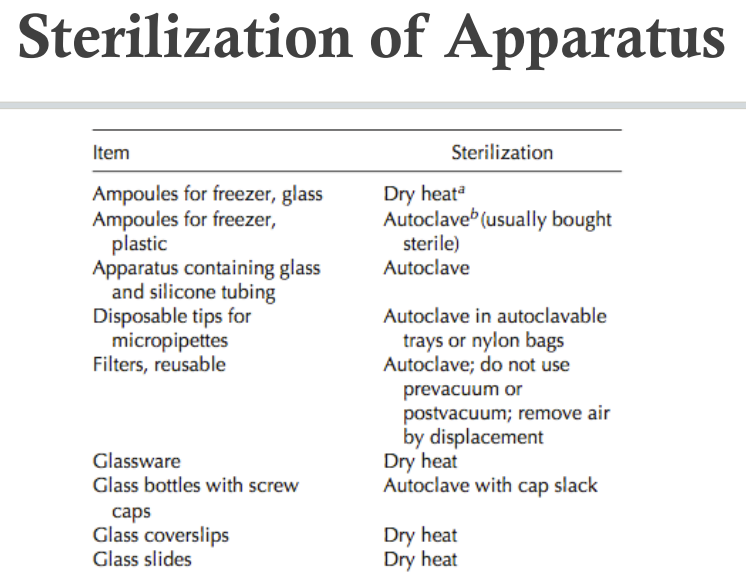

- metal→dry heat

- silicone rubber PTFE PCO3 cellulose acetate/nitrate filter→autoclave

- cleaning

- Methods

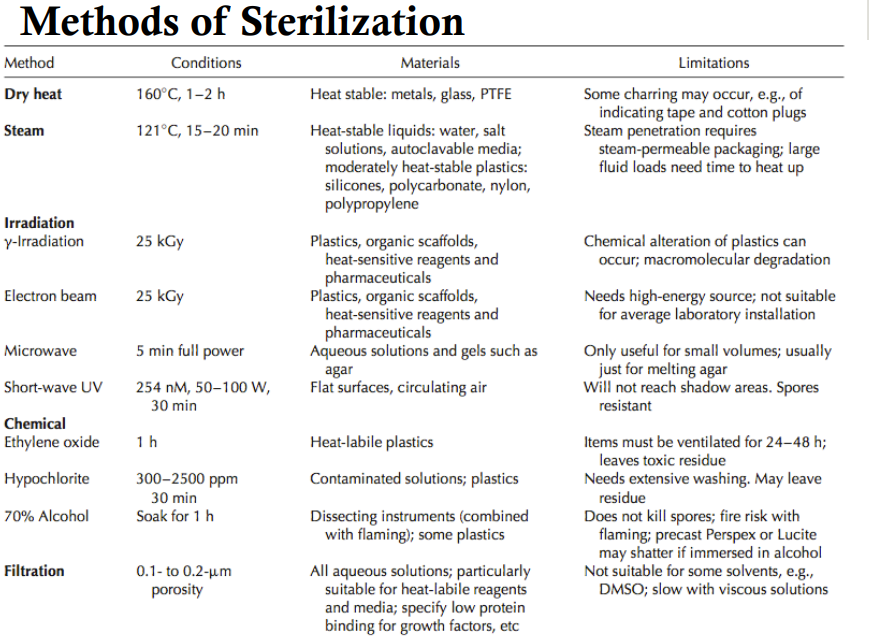

- dry heat→160C 1-2h

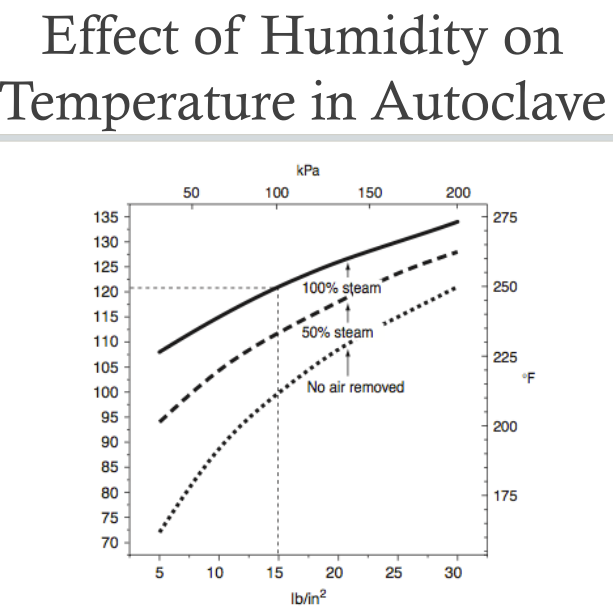

- moist heat→121C 20m

- glass

- moist heat with loose cap & autoclave tape, autoclave at 121C for 20m

- slack cap allow steam enter bottle and tighten it after cool down

- dry heat preferable

- thermalog indicator turns blue with high temp & steam→safe

- surface also need to carry correct charge for cell propagation

- caustic alkaline detergents render surface not suit for cell attachment→neutralize with 0.1M HCl/H2SO4

- detergent remove residue

- no toxic residue left behind to leach out into medium/reagent

- detergent→7X, MP Biomedicals, Decon

- Alternative

- Immerse in 70% alcohol for 30 min, dry them off under UV light in a laminar flow hood

- Ethylene oxide but 2-3 weeks are required to clear it completely from the plastic surface

- γ- irradiation at 25kGy

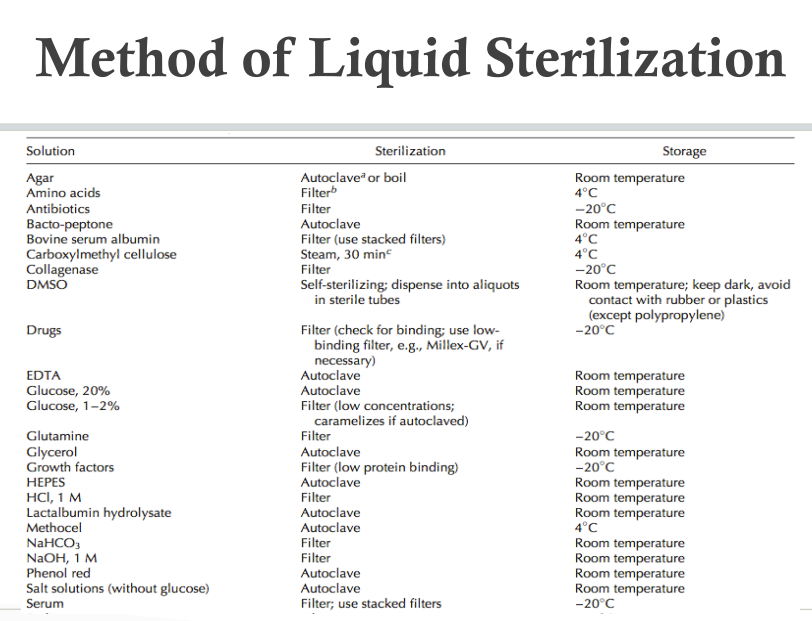

- Liquid sterilization

- avoid accidental inclusion of toxic substance

- enable reagent to be totally defined & fx of its constituents to be fully understood

- reduce risk of microbial contamination

- Reagents & media

- water purification

- 1 rinse glassware & reagent prepare→glass distillation, reverse osmosis

- 2 remove both organic & inorganic colloids→carbon filtration

- 3 remove ionized inorganic materials→high grade mixed bed deionization

- final removes microbe, trap resin may escaped from deionizer→micropore filtration

- ultrapure water if water is recycled continuously from micropore filter to reservoir

- water purification

- Media preparation

- commercial

- working strength solution 1x w or w/o glu→direct use

- 10x concentrates w/o NaCO3 & glu→dilute first

- powder w/w/o NaCO3 & glu→cheapest, not sterile, 10x concentrates cost 2-3x powder media but save on sterilization, 1x media most expensive & convenient

- adjust pH→alkali neutralize 10x concentrated medium

- +NaCO3→stable equilibrium with atmospheric CO2

- addition to medium→glu is unstable

- QC→check by incubate aliquot of complete medium at 37C for 48h before use

- commercial

- Media sterilization

- autoclave

- less labor intensive, less expensive, low failure

- buffer pH 4.25 with succinate to stabilize VB

- glu replaced by glutamate/glutamyl dipeptide/added sterile after autoclave

- sterile filtration

- for heat labile solution

- filter thro 0.1-0.2 um PES, PCO3, PTFE, cellulose acetate

- -+pressure from a pressurized container/peristaltic pump

- in-line + peristaltic pump 100L

- bottle-top + vacuum pump 10L

- large scale 100-10kL

- autoclave

Comments

Post a Comment